| Brand: | JK Impex |

| Model: | S7 |

| Country: | India |

| Signal Output : | UART PWM |

| Detection Principle: | MIE sphercial scattering |

| Detection Range: | ≥5μm |

| Working Current: | ≤30mA |

| Standby Current: | ≤0.5mA |

| Storge Conditions: | -10~65℃ , 0~98% RH |

Introduction of S7 Smart Dust Sensor

S7 Smart Dust Sensor can accurately detect the number and concentration of particles inventilation ducts passing through the handle of vacuum cleaner or extension rod pipeline,sweeping robot, lampblackextractor, particle detection instrument and other equipment byusing the principle of optical alignment.

1.1 Application Benefit of S7 Smart Dust Sensor in Robot Vacuums and Robot Sweeping Products

◆ The clean effect of the equipment and the cleanliness of the ground, carpet and bed sheet are presented

intuitively to users through sensor output data and LED color display.

◆ The device intelligently controls the speed of the motor according to the sensor data to achieve silence,

energy saving and prolong the life of the motor.

Characteristics of S7 Smart Dust Sensor

◆ This product apply in wide voltage range from 12V to 30V, which can be directly powered by the PWM signal cable of driving motor.

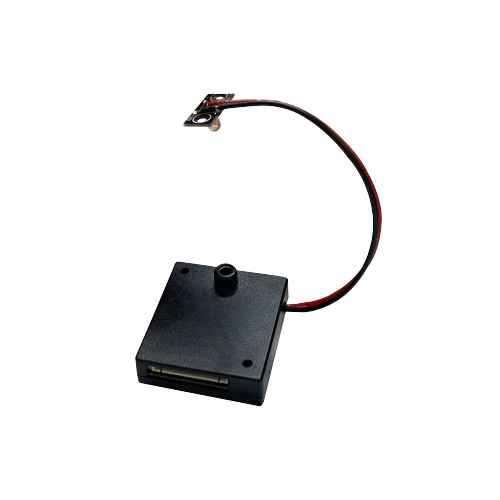

◆ The product adopts the separated structure of transmitting and receiving counter-shooting, which is small in size and convenient for users to install and use flexibly in various complex structures: receiving host dimension: L34*W30*H8.5mm, transmitting terminal dimension: L15*W7*H6.5;

◆ High detection accuracy in motion, and the minimum detected particle size is 10um with wind speed at 12m/s.

◆ High sensitivity in detection, with the response time less than 0.3s.

◆ The detection ranges are wide with two options from 0 to 999 or 0 to 9999.

◆ Low power consumption: working current is less than 30 mA and standby curent is less than 0.5 mA.

◆ The output interface's 3 PIN control LED driving level to indicate 7 kinds of color, which can be connected with LED indicator light outside.

◆ Particle Concentration Data Output Interface: PWM, UART can provide accurate dust concentration data for vacuum cleaner, sweeping robot and other equipment in real time.

Application Area

◆ Kitchen exhaust hoods

◆ Intelligent detectors

◆ Sweeping Robots

◆ Vacuum cleaners

1.4 Basic Characteristics

◆ In principle, this product is only applicable to the above application areas. Users need to verify it for other purposes.

◆ Please keep this product as far away from the source of high frequency and high voltage as possible to avoid interference caused by high frequency and high voltage.

◆ The irregular violent vibration may cause the measurement error of this product.

◆ External light may cause the measurement error of this product. Therefore, when installing the equipment, it is necessary to avoid the external light as far as possible.

Notes to Circuit design:

1. Data communication and control pin of S7 output interface need 3.3V as high level. [The motherboard MCU requires power supply 5V, and needs to add level conversion chips or circuits to communication lines (RXD, TXD) and control lines (SET, RESET)]

2. SET and RESET have pull-up resistor, if not used, it should be suspended.

3. PIN7 is used for internal debugging of the program and should be suspended in the application circuit.

4. Sensor VDD output voltage + 3.3 VDC, load current 20 mA at Max.

5. R\G\Y drive output needs to be connected to the peripheral conversion circuit. For example, the circuit in

Data Transmission

UART output

The sensor uses standard full duplex UART serial communication with a baud rate of 9600 bps. In the application process, only the dust concentration data are received. The sensor works continuously by default. After decoding the serial data, the dust concentration value is obtained in the unit of mg/m2. Detailed serial communication format and data decoding refer to Appendix 1.

PWM output

The sensor outputs the PWM signal through the PWM port. The PWM period is 1s, and the dust concentration value is calculated according to the low level width.

The relationship between low pulse time and dust concentration is 1 ms = 1 mg/m2. For example, the low level width is 100 ms corresponds to 100 mg/m dust concentration. The output range of PWM concentration ranges from 5 mg/m2 to 800mg/m2.

Installation Attentions

◆ The transmitting tube and the sensor body are connected by calbes;

◆ It should be assured that the distance between the transmitting tube and the receiving tube is 180°;

◆ The distance between the transmitting tube and the receiving tube should be less than or equal to 60 mm